High-end tube amplifiers rely on output transformers. Discover why output transformer design defines control, dynamics, and musical realism.

The Role of Output Transformers

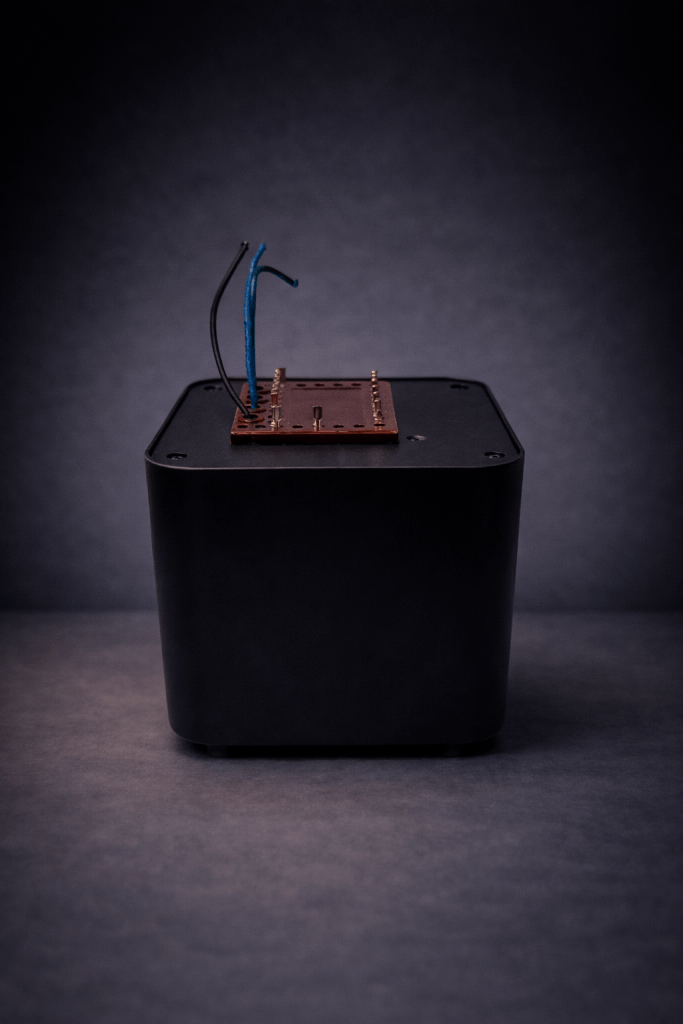

Every PrimaLuna Tube Amplifiers high-end tube amplifier has its own “black boxes.” The output transformers. Crucial for musical success. This is where the power of the tubes is converted into control, dynamics, and tone color. There is nothing to mask here. Anything that is poorly designed and therefore incorrect is exposed to the ear.

The Heart of a Tube Amplifier

Even though the output transformer is at the “end” of the amplification path, consider it the heart of the amplifier. Designed for linear behavior across the entire audio bandwidth. Free from compression at high peaks. Stable, even with difficult speaker loads.

Design Is Not Optional

Tubes can be replaced. But in most cases, an output transformer is a fixed choice. It is therefore important that the designer makes the right choice within the overall tube amp design. The desired high sound quality is not a promise, but a matter of course.

What things can cause an output transformer to malfunction? I ask because a year ago I had to get my Prologue Two fixed due to a faulty transformer which showed a crackling noise on one channel after about 20 years of service. I always took good care of it as in fact it still looks brand new!

Thanks

Regards

Mike

Dear Michael,

Apparently, there are quite a few possible causes, including:

Ageing of the winding insulation

Internal breakdown between windings

Moisture absorbed by the paper insulation

Thermal damage caused by prolonged operation under load

Poor internal solder or welded connections

Corrosion of the lead wires

Mechanical stress or windings that have come loose over time

DC offset due to a faulty output tube or an incorrect bias setting

That said, the most likely explanation is very slight internal breakdown between the windings. This can happen when the insulation of the winding wire deteriorates after the transformer has been running too hot for too long, or simply as a result of natural ageing.

Thanks for your reply.

Regards

Mike